2018

founded

110

Countries

1350

Dealers

Our story

Sometimes the best ideas come from the worst experiences. After a clipless mountain biking accident, founders Paul Wessiack and Harald Himmler set out to revolutionize bike pedal safety. Their solution? Magnetic pedals that offered the efficiency of clipless pedals without the risk. A successful Kickstarter campaign in 2018 launched magped and our patented magnetic system to the world, and the rest is history. We remain committed to uncompromising quality, ensuring our products deliver peace of mind and performance for every ride.

- safe

- innovative

Elevate your ride with magped

Feel the power. Feel the freedom. From the moment you hear that satisfying click between magnet and shoe plate, our pedals deliver a seamless connection to your bike. With instant engagement, superior grip, more efficiency, and effortless release, you’re ready to explore without fear. Experience the magped difference today. The magnetic force acts primarily vertically upwards. Lateral release in all directions is possible at any time and easily – even in critical situations. Experience completely stress-free biking without fear with magped.

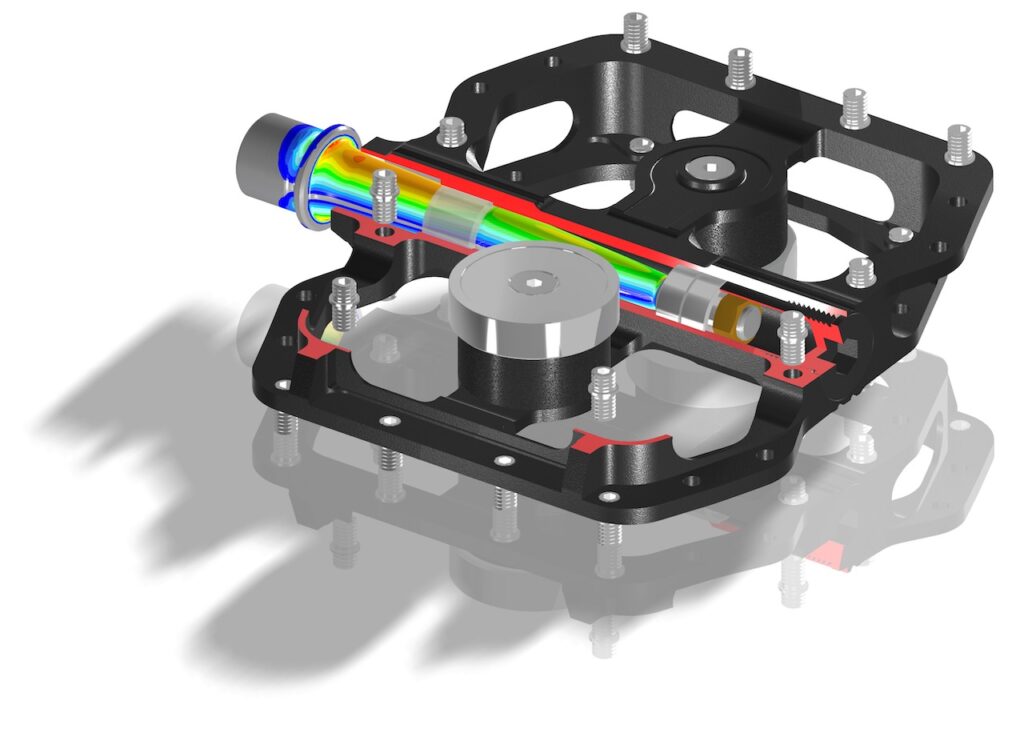

Precision European Engineering

We use advanced finite element methods (FEM) simulations to design and optimize magnetic pedals that are both incredibly strong and lightweight. Via strength verification and bionics principles, our engineers rigourously analyze every detail of the pedal to ensure it can withstand the toughest conditions. This meticulous process guarantees that every magped pedal is built to last.

Tested to perfection

Our pedals undergo intense testing, both on and off the bike. Our riders put prototypes through their paces for countless hours, while our in-house test stand simulates real-world conditions.

Once development is complete, independent experts at the German Zedler Institute officially verify our pedals for safety and durability. This ensures that every magped pedal meets the highest standards of quality.

Why magped pedals?

Designed in Austria by automotive engineers, we are dedicated to innovation, quality and performance.

Magped magnetic pedals are not equipped with a firm mechanical connection comparable to standard clipless pedals. The magnetic force is impacted by several factors e.g. magnet size, dirt, wear and direction of force applied. An unintended disconnection from the pedals is possible at any point of time.

Meet our team

Chefdesigner

Harald Himmler

What I do for fun? MTB, kitesurfing, skiing. Tinkering on new ideas.

ENGENEER

Hias Peer

What I do for fun? motorcycling, sailing, MTB.

GRAPHIC DESIGNER

Katja Wessiack

What I do for fun? MTB, Yoga. Be creative all the time.

ENGINEER AND TESTER

Paul Wessiack

What I do for fun? MTB, kitesurfing. Peace, quite and space to be creative.

Deutsch

Deutsch Italiano

Italiano Français

Français